Maintaining Your Servo Voltage Stabilizer: Tips for Long Life and Reliable Performance

Servo voltage stabilizers play a crucial role in ensuring a stable power supply, protecting your equipment from voltage fluctuations. To maximize their lifespan and maintain reliable performance, regular maintenance is essential. Here are some practical tips to help you keep your servo voltage stabilizer in optimal condition.

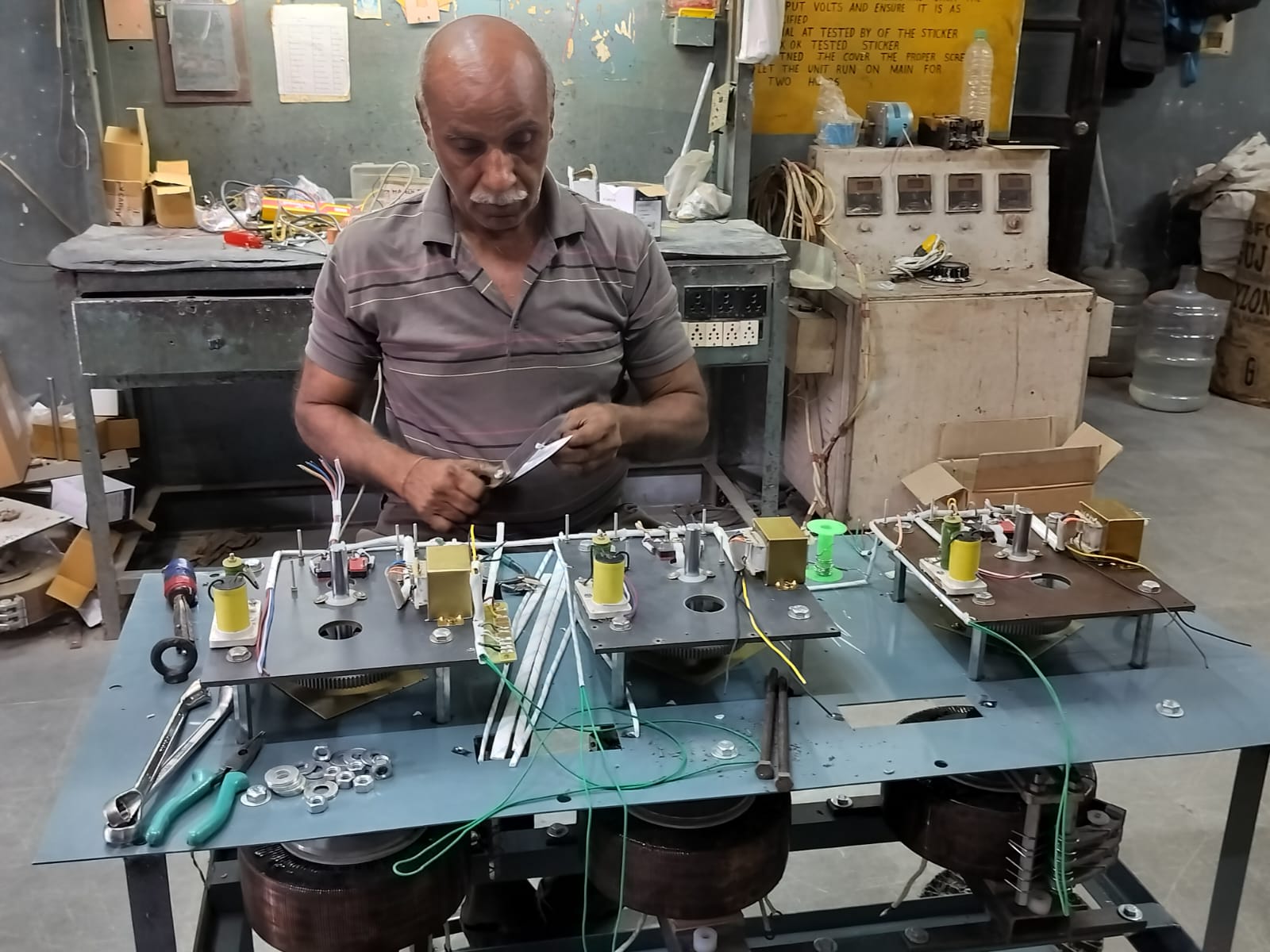

1. Regular Visual Inspections

Perform regular visual inspections of your servo voltage stabilizer. Check for any signs of physical damage, such as dents, cracks, or loose components. Ensure that all connections are secure and free from corrosion. Identifying and addressing physical issues early can prevent more significant problems down the line.

2. Keep It Clean

Dust and debris can accumulate on and inside your stabilizer, affecting its performance and cooling efficiency. Regularly clean the exterior surfaces using a dry, soft cloth. For internal components, consider using compressed air to remove dust. Ensure that the stabilizer is powered off and disconnected from the power supply before cleaning.

3. Monitor Cooling Systems

Proper cooling is vital for the efficient operation of your servo voltage stabilizer. For air-cooled stabilizers, ensure that the ventilation openings are not blocked and that air can flow freely. For oil-cooled stabilizers, check the oil levels and quality periodically. Replace the oil as recommended by the manufacturer to maintain optimal cooling performance.

4. Check Electrical Connections

Loose or corroded electrical connections can lead to voltage drops and inefficient performance. Periodically inspect all electrical connections and tighten them as needed. Use a non-corrosive contact cleaner to clean any contacts that show signs of corrosion. Proper electrical connections ensure efficient voltage regulation and prevent potential malfunctions.

5. Test Voltage Output

Regularly test the voltage output of your stabilizer to ensure it is operating within the specified range. Use a reliable multimeter to measure the output voltage and compare it with the stabilizer’s settings. If the output voltage is consistently outside the acceptable range, it may indicate an internal issue that requires professional attention.

6. Perform Preventive Maintenance

Adopt a preventive maintenance schedule based on the manufacturer’s recommendations. This may include periodic inspections, cleaning, testing, and component replacements. Keeping a log of maintenance activities can help track the stabilizer’s condition and identify patterns that may indicate potential problems.

7. Address Issues Promptly

If you notice any unusual sounds, smells, or performance issues, address them promptly. Unresolved problems can escalate and lead to significant damage or downtime. Consult the user manual for troubleshooting tips or contact a professional technician for assistance.

8. Professional Servicing

While regular maintenance can be performed by the user, it’s essential to have your servo voltage stabilizer serviced by a professional at least once a year. Professional technicians have the expertise and tools to perform thorough inspections, diagnostics, and repairs, ensuring that your stabilizer remains in top condition.

9. Use Genuine Parts

When replacing components, always use genuine parts recommended by the manufacturer. Using counterfeit or substandard parts can compromise the stabilizer’s performance and safety. Genuine parts are designed to meet the specific requirements of your stabilizer and ensure its reliability.

10. Keep Up with Software Updates

For stabilizers with digital controls, check for firmware or software updates from the manufacturer. Keeping the software up-to-date can improve performance, fix bugs, and add new features that enhance the stabilizer’s functionality.

Conclusion

Maintaining your servo voltage stabilizer is crucial for ensuring its longevity and reliable performance. Regular inspections, cleaning, and professional servicing are key practices to keep your stabilizer in optimal condition. By following these practical maintenance tips, you can protect your equipment from voltage fluctuations and ensure a stable power supply for years to come. At Stabiline Systems, we’re committed to helping you achieve the best performance from your power solutions. If you have any questions or need professional maintenance services, our expert team is here to assist you.